Mechanical and

fixture engineering

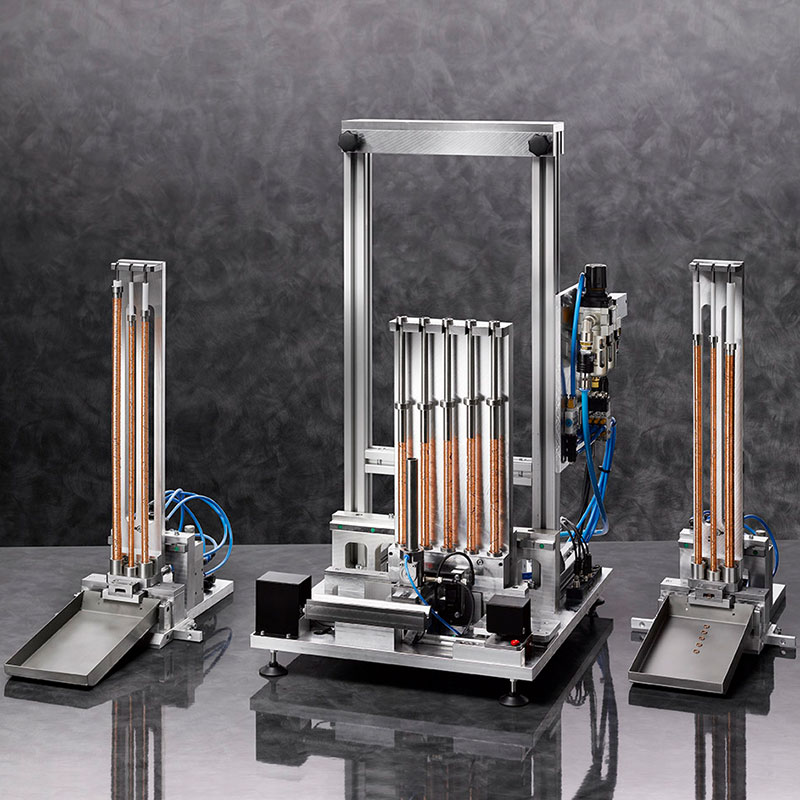

Our longtime experience in the field of mechanical and fixture engineering contains the whole process chain, starting with the conception, through the development, to the construction, the manufacturing and assembling.

Since we manufacture everything in-house, you get everything from a single source and there are no additional delivery times.

Our product range includes amongst others:

- Test- and assembling jigs

- Prototype- and series jigs

- Automatic montage of solder rings

- Leak testing machinery and -fixtures

- Test- and assembling equipments

Industry solutions

Our customers use our machines in the areas of joining technology, dimensional control and also in downstream steps such as testing and assembly processes. We also develop the right machine for you.

Our machines are used in the following areas:

- Automotive industry

- Medical engineering

- Aircraft industry

- Electrical engineering

- Air conditioning and refrigeration technology

- Tool industry

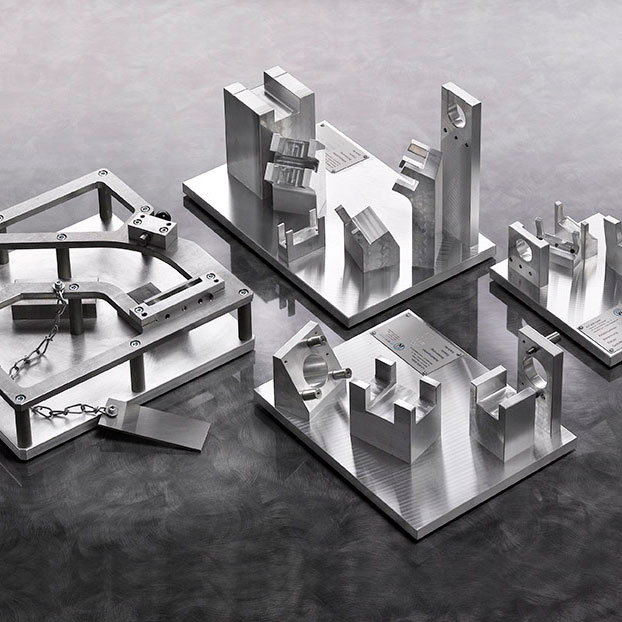

Many of our customers rely on different designs from our company in the area of testing gauges. We differentiate between form gauges, sealing and test gauges. If required, we can also offer you combinations. This saves you costs and effort in storage and use.

Our offer is not limited to gauges and machines. Many of our customers rely on our solutions in the area of welding devices, assembly aids and devices. As with all products, we do not fall back on a standard repertoire, but always work out individual solutions. Our focus is on easy handling for the worker, reliable, reproducible results and the most cost-effective use of components with maximum reliability.

Problem statement

In an initial appointment, we coordinate the requirements with the customer and look for possible solution approaches together. Keep it simple: Our goal is always the simplest possible solutions with a positive cost-benefit effect.

Concept development

After defining the possible solutions, our team goes into the concept phase. Well planned is half implemented. It has proven itself in our company to invest more effort in the concept and to play through eventualities. Later, this will help save valuable time and money. At the end of the concept phase, there is a realizable solution with a concrete offer.

Construction

After completing the design phase, we start working on the concept in detail. During the conception we rely on 3D CAD models, which do not only serve as a preliminary model of the later machine or device. Rather, we simulate the individual movements, e.g. to better represent handling processes. We are able to react quickly and flexibly to change requests. A close exchange with you as a customer is very important to us in this phase in order to precisely cover all requirements and to ensure a smooth implementation of the project.

Purchasing of material and semi-finished parts

The optimum material for your product: We at H.P. Wirth know the requirements of the various industries and, thanks to many years of experience, have optimally tailored our use of materials to it. For example, we are happy to take on the procurement of special alloys in the steel sector amongst other things, to give just one example. We maintain long-term partnerships with our suppliers so that we can always be supplied promptly and reliably. By request, we can also purchase the materials directly from your supplier. This applies to semi-finished products as well as to purchased parts of any kind.

Our standard corresponds to your preferred list and your requirements. We are happy to support you in the selection of materials through our many years of experience.

We are open to new or customer-specific materials for various applications. Thanks to our own production, we can not only respond to your individual needs, but also to the requirements of the respective materials.

Manufacturing

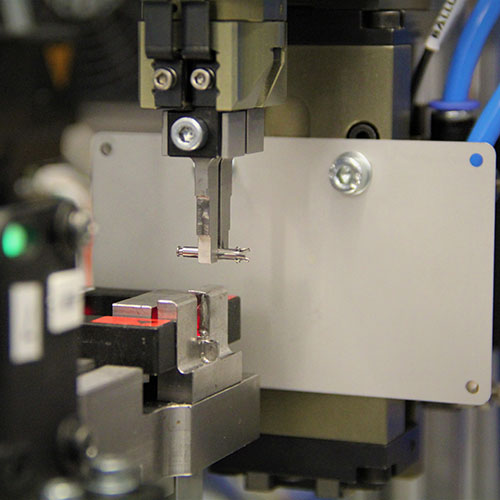

Sawing, milling, turning, grinding, welding - everything is done in-house. Short distances generate a fast response time: Due to our enormous vertical range of manufacture, we can respond flexibly to your wishes at any time and react quickly to emerging challenges and carry out optimizations during the entire project process.

Experiment / test phase

After completion, the machines are run in and tested in-house with customer parts. If you as a customer and also, we are satisfied with the result, we will supply you with an operational machine.

Implementing / Service

Our experienced employees put the system into operation at your company and train your team. H.P. Wirth offers a comprehensive service with short response times: this includes regular maintenance and a long-term, fast supply of spare parts.