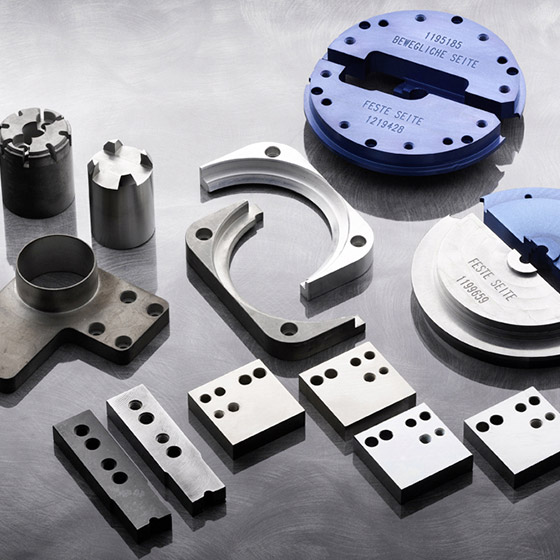

Contract

manufacturing &

machining

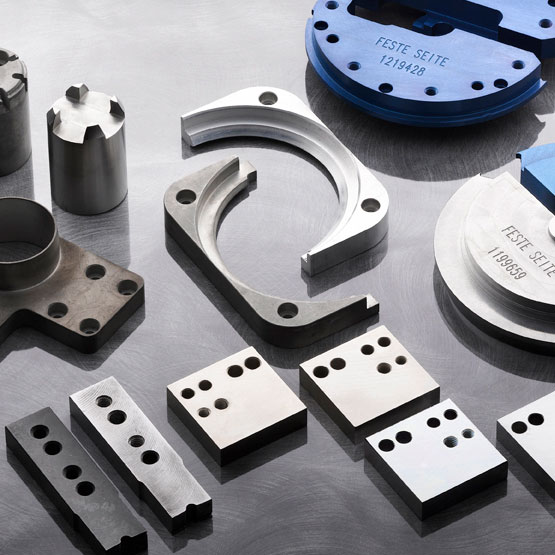

Turning, milling, welding

Whether turning, milling or welding - we take over the production for you from a quantity of 1. In addition to modern machinery, we have years of know-how. In this way we can respond flexibly to customer requests and guarantee precise results. We take care of your order holistically.

Finishing

Whether heat treatment or surface coating – we take on the finishing of your parts. In this connection we are totally guided by your requirements. Our options, in collaboration with reliable component suppliers, range from chrome plating to simple hardening or nitriding to powder coating or painting. We are happy to offer you the final refinement together with mechanical processing or complete production of your components / assemblies.

Samples

You often need samples for internal trials in order to test a first estimation of manageability, size or also function. Here we are at your disposal as a partner. We are willing to implement several sample variants or developments together with you. Since our production processes and the vertical range of manufacture basically permit production from a quantity of 1, we are able to react quickly to your wishes.

If you need sample parts from the punching and bending area for a test, we can design and offer you an auxiliary tool, as well as take over the production of your sample parts. For this we have different manual workstations as well as machines to realize different quantities in full spectrum.

Machinery

Our machinery is constantly being expanded. Thereby we can guarantee our extraordinary in-house production depth. In the following table you can get a gross summary about our actual manufacturing possibilities and the maximum values, which result from our machinery.

| Milling | |

| 3 axial CNC milling | max. travelling distance 1,067 x 670 x 610 mm |

| Conventional milling | max. travelling distance 800 x 600 x 500 mm |

| Turning | |

| Universal CNC turning center | max. turning diameter 410 mm, max. workpiece length 550 mm |

| Conventional turning | max. turning diameter 300 mm, max. workpiece length 1,000 mm |

| Grinding | |

| Surface grinding | max. component size 500 x 200 x 250 mm |

| Cylindrical grinding | max. workpiece diameter, 100 mm, max. workpiece length 400 mm |

| Measuring technique | |

| Coordinate measuring machine | max. travelling distance 700 x 1,000 x 600 mm |

| Optical measuring projector | measuring range 200 x 200 x 75 mm |

| Cleaning of workpiece | |

| Washing and degreasing plant | single coyote chamber flushing system with modified alcohol, dimensions of cage 530 x 320 x 200 mm |

| Stamping and bending technology | |

| Bihler stamping and bending machine | press capacity up to 7 t |

| Bruderer stamping machine | press capacity 30 t |

| Heat treating | |

| Hardening furnaces | max. temperature 1,100 °C |

| Chamber convection oven | max. temperature 600 °C |

Quality

Not only in the field of mass production we emphasize maximum quality. We also strive to achieve perfect results both in the manufacture of individual components and in the field of mechanical engineering. We use various measuring devices according to the latest standard here: different optical test equipment as well as coordinate measuring machines. We would be glad to provide you with your components including a measurement report on request.

Our machines are used in the following areas:

- Automotive industry

- Medical engineering

- Aircraft industry

- Electrical engineering

- Air conditioning and refrigeration technology

- Tool industry